Are Toys from China Subject to Tariffs? Guide for Importers

Confused about tariffs on Chinese toys? This article breaks down current rules, exemptions, and how toy imports are affected.

#1 Toys Manufacturer in China. WhatsApp: +86 180-0088-4063. Email: [email protected]

#1 Toys Manufacturer in China. WhatsApp: +86 180-0088-4063. Email: [email protected]

Finding the right air dry clay manufacturer is a critical step in ensuring your business’s success. Air dry clay is not only a popular crafting material but also an essential part of the toy and educational industries. Choosing the right manufacturer impacts the quality of your products, your brand reputation, and ultimately, customer satisfaction.

A reliable manufacturer can make the difference between running into issues with supply and having a seamless, long-term partnership.

When selecting a reliable air dry clay manufacturer, several key factors must be taken into account to ensure your business’s success. It’s not just about finding a supplier who can deliver large quantities. Instead, you need a partner who meets your specific needs, from product quality to customization options.

Product quality and safety standards are vital when working with air dry clay, especially in the toy and educational sectors.

Look for certifications that guarantee safety and compliance with international standards, such as ASTM (American Society for Testing and Materials), EN71 (European safety standard for toys), and ISO (International Organization for Standardization). These certifications help to verify that the air dry clay has undergone rigorous testing for safety and quality.

Additionally, make sure the manufacturer follows quality assurance procedures, including batch testing and third-party inspections, to maintain consistent product standards.

A reliable manufacturer should have clear protocols in place to ensure that each batch of air dry clay meets established quality standards. This not only reduces the likelihood of defects but also ensures that the product performs as expected.

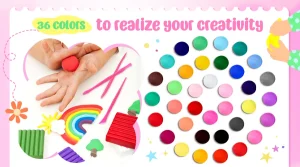

Manufacturing capabilities play a crucial role in selecting the right air dry clay supplier. When you need custom branded air dry clay, the manufacturer should offer flexibility in customization. This includes the ability to alter the color, packaging, and even the formulation to fit your business needs.

Customization options can help set your brand apart in the market, whether you’re selling air dry clay in vibrant colors or offering special scents or textures.

Some manufacturers may require large MOQs, which could be problematic if you’re just starting or need smaller batches. Discuss your requirements and see if the supplier is willing to accommodate lower MOQs or offer scalable solutions.

This might include adding a unique texture or scent to the air dry clay, or developing specific formulations for particular uses, such as craft projects, educational toys, or even therapeutic purposes. These customized features not only give your product a unique edge but also help it meet the specific needs of your target market.

>> Fun and Educational: Lightweight Clay Projects for Kids

When choosing a reliable air dry clay manufacturer, understanding the company’s reputation and track record is crucial.

A manufacturer’s history in the market can provide valuable insights into their reliability, product quality, and commitment to customer satisfaction. A strong reputation not only indicates trustworthiness but also suggests a manufacturer’s ability to deliver consistent results over time.

One of the first steps in researching a manufacturer’s reputation is to check reviews, testimonials, and case studies. These sources offer direct feedback from businesses who have worked with the manufacturer before.

In addition to online reviews, look for detailed case studies that showcase the manufacturer’s past projects, particularly those relevant to the air dry clay market.

Don’t forget to evaluate the manufacturer’s customer support and after-sales services. A reliable manufacturer should offer accessible and responsive support during and after the purchasing process.

Whether you have questions about the air dry clay’s quality, need help with shipping, or encounter issues with the product, efficient customer service can make all the difference in your business relationship.

The level of experience a manufacturer has in the air dry clay market is another important factor to consider. A manufacturer with years of experience understands the nuances of production, material sourcing, and quality control. This expertise ensures that the air dry clay you receive will meet high standards, consistently and reliably.

Their familiarity with the needs of these markets—such as compliance with safety regulations, packaging requirements, and production timelines—means they can be more responsive to your business demands.

Previous partnerships with reputable companies often indicate that the manufacturer can deliver as promised.

A seasoned manufacturer has refined their processes over time, leading to fewer defects, better quality control, and efficient production. This can be especially important for businesses that rely on consistent, high-quality air dry clay to meet customer demand without delays or quality issues.

When choosing a manufacturer for your air dry clay, understanding their production lead times and reliability is critical to the smooth operation of your business. Timely delivery and consistent product quality are essential to meet your customer demands and avoid unnecessary disruptions.

Setting clear expectations for production timelines is crucial when working with an air dry clay manufacturer. It’s important to know the estimated lead times for orders and any potential variability due to factors like seasonal demand or production capacity.

Dealing with unexpected delays is inevitable in manufacturing, but managing these risks is equally important.

Understanding how they handle delays and how they communicate with clients can help you prepare for any unexpected setbacks.

Timely deliveries are not just about convenience; they affect your overall business operations. When air dry clay shipments arrive as scheduled, you can maintain consistent stock levels and avoid downtime.

Delays can result in missed sales opportunities, dissatisfied customers, and a tarnished reputation. Thus, ensuring a dependable delivery schedule can be a game-changer for your business.

>> Certifications for Toy Safety: Regulations You Must Know

A key component of assessing a manufacturer’s reliability is understanding their quality control process. For air dry clay, consistency in texture, color, and drying time is crucial. Manufacturers should have clearly defined procedures in place to monitor the quality of each batch from start to finish.

Inspections and testing are integral to maintaining consistency in production.

Manufacturers should conduct thorough checks at each production stage, including raw material inspection, mixing, drying, and packaging. Regular testing helps identify issues early and ensures that the air dry clay meets industry standards and your specific requirements.

To further guarantee product consistency, some manufacturers use batch-to-batch tracking. This process ensures that each batch of air dry clay is traceable, and any deviations can be quickly identified and addressed.

As a business owner, it’s essential to establish a strategy with your manufacturer to ensure that every batch meets your standards for color, texture, and drying performance.

When selecting an air dry clay manufacturer for your business, it’s essential to understand their pricing and payment terms. The cost of air dry clay can vary widely based on factors like quality, quantity, and additional services, so evaluating these aspects will help you make an informed decision.

To make sure you’re getting the best deal for your air dry clay, start by comparing pricing across different manufacturers.

While price is important, it’s equally vital not to compromise on quality. Cheaper options might seem appealing, but they could result in subpar products that don’t meet your standards or customer expectations. Focus on finding a balance between price and quality.

For example, ask about the cost per unit of air dry clay, additional charges for customization, or special additives.

Manufacturers may have different pricing models depending on the size of the order or the complexity of the formulation. Make sure to get a clear and detailed pricing structure to avoid hidden fees later on.

Depending on your location and the manufacturer’s location, shipping can either be a major expense or a small one. Ensure that the manufacturer provides transparent shipping costs, including any duties, taxes, or handling fees, so you can accurately calculate your total cost.

Payment terms are another key factor when working with an air dry clay manufacturer.

Different manufacturers may offer different payment options, such as bank transfers, letters of credit, or payment upon delivery. Understand what payment options the manufacturer offers and how flexible they are with terms, especially if you’re a new customer or a smaller business.

Discuss the payment schedule—whether it’s a deposit upfront, full payment before shipping, or a balance upon delivery.

If you’re negotiating larger orders, see if the manufacturer is willing to offer installment payments. It’s also a good idea to clarify payment methods accepted, such as wire transfers, credit cards, or PayPal, depending on your business’s preferences.

Verify any late fees, discounts for early payments, and refund policies in case of order cancellations or delays. Clear communication on payment terms from the beginning can save your business from unexpected charges or delays in receiving your air dry clay orders.

When working with an air dry clay manufacturer, it’s important to think beyond production and focus on logistics, shipping, and delivery. These factors can significantly affect your overall cost and timelines.

Efficient logistics will ensure that your air dry clay products arrive on time and within budget, so you can meet customer demands without unnecessary delays.

Shipping costs can quickly add up, impacting the final price of your air dry clay products. It’s important to understand how these costs will affect your business’s bottom line, especially if you’re ordering in bulk.

Shipping fees vary depending on the distance, the weight of your order, and the delivery method. Be sure to factor these costs into your overall budget when negotiating with manufacturers.

Ordering in bulk and having larger shipments sent at once can help you secure discounts. Many manufacturers offer bulk order discounts or reduced shipping rates for large orders, which can save you money in the long run.

Also, ask manufacturers if they have preferred shipping partners or options that might reduce costs.

Be clear about your required delivery times, and work together to plan the most cost-effective shipping method. Additionally, look into options like ocean freight for longer distances or air freight for faster delivery, depending on your business’s urgency and cost constraints.

If your air dry clay manufacturer is overseas, understanding international shipping and customs is critical.

Customs duties, taxes, and import laws vary by country, so be prepared for these additional costs when receiving shipments. Work with a customs broker or a logistics expert to help navigate the complex rules of international trade and avoid costly mistakes.

This includes commercial invoices, packing lists, and certificates of origin. Double-check with your manufacturer that they are providing accurate and complete paperwork, as missing or incorrect documents can cause delays in customs.

It’s also a good idea to stay updated on the import laws of your destination country. Customs regulations can change, and what was once a smooth process could face new hurdles.

Keeping track of these changes can save you time and avoid the headache of unexpected delays. By planning ahead, you can ensure your air dry clay shipments clear customs quickly, arriving at your business without issue.

In today’s world, businesses are increasingly focusing on sustainability and ethics. Choosing an air dry clay manufacturer that aligns with these values is important not just for your business, but for your customers as well. Sustainable and ethical practices contribute to a positive brand image and can build stronger relationships with your clients.

Sustainability has become a priority for many companies, especially in the toy and craft industry. With growing concern about the environment, more manufacturers are shifting towards eco-friendly materials and production methods.

This includes using non-toxic, biodegradable ingredients in their air dry clay products, as well as adopting energy-efficient manufacturing processes.

If your business prioritizes the environment, working with an eco-conscious manufacturer reflects that commitment. It shows that you care about the impact your products have on the planet, whether it’s through recyclable packaging or using renewable energy sources in production.

A reliable manufacturer will be open about their materials, processes, and efforts to reduce their environmental footprint. Transparency builds trust and ensures that your business is aligned with environmentally responsible practices.

Just as sustainability is crucial, so are ethical labor practices. The importance of fair wages and safe working conditions cannot be overstated.

Manufacturers that adhere to ethical labor practices ensure that their workers are treated fairly, with respect and dignity. This includes paying fair wages, providing safe working conditions, and upholding basic human rights.

You can do this by looking for certifications like Fair Trade, SA8000, or audits by third-party organizations. These certifications indicate that the manufacturer is held accountable for their labor practices and is committed to the welfare of their employees.

By partnering with manufacturers who uphold fair labor practices, you build trust with your customers, showcasing that your business cares about both the planet and the people behind your products. This can lead to a stronger, more loyal customer base who value integrity and transparency.

Once you’ve chosen the right air dry clay manufacturer and the products are on their way, the relationship doesn’t end there. Post-sales support is a key aspect of maintaining a successful partnership.

A reliable manufacturer should be ready to address issues that arise, handle returns, and provide assistance when needed. Long-term relationships also require continuous effort to ensure both sides benefit over time.

Issues with defective products or returns can occur, even with the best manufacturers. When choosing an air dry clay manufacturer, it’s essential to understand their return and warranty policies.

Make sure you know the steps involved in returning products, the time frame for returns, and the process for getting replacements if needed. A manufacturer with clear and fair return policies ensures smooth business operations and customer satisfaction.

Communicate clearly with the manufacturer about the issue and provide evidence (such as photos) to speed up the process.

Having an established plan for product recalls, if necessary, will also protect your business reputation. It’s vital to ensure that the manufacturer can work with you to resolve these issues swiftly.

It reduces stress and ensures that your customers or clients are not left in the lurch, helping to keep your reputation intact.

A strong, long-term relationship with your air dry clay manufacturer can bring significant benefits. It fosters trust and better collaboration, allowing both parties to anticipate and meet each other’s needs.

By maintaining an open line of communication, you can address any issues early on and ensure continuous improvement in both product quality and production processes.

As your business expands, your clay needs might change, and a long-term partner will be more likely to accommodate those shifts. Regular feedback, whether it’s about product quality or delivery schedules, can help fine-tune operations and make the partnership stronger.

Building trust and showing loyalty over time can lead to better pricing, priority in production, and other business advantages. A well-established relationship not only makes day-to-day transactions smoother but also paves the way for future success.

Choosing a reliable air dry clay manufacturer is essential for your business’s success. Focus on evaluating production timelines, pricing, sustainability, and post-sales support. Building a long-term partnership with a trustworthy manufacturer ensures consistent quality and smooth operations, setting you up for growth and stability.

When assessing a manufacturer’s facility, focus on cleanliness, organization, and the technology they use. A well-maintained facility ensures consistent product quality and efficient production processes. Check if they have quality control checks at every stage, from raw materials to final packaging.

Many manufacturers offer customization in terms of color, texture, and packaging. Before committing, ask the manufacturer about their flexibility in adapting to your specific product needs. Ensure they have a track record of successfully handling custom orders and can meet your timelines.

A trustworthy manufacturer should conduct various tests, such as texture, drying time, and durability tests. They may also test for safety standards, ensuring that their air dry clay is free of harmful chemicals and complies with regulatory guidelines. Ask for test reports to confirm the quality.

Look for manufacturers who provide clear documentation about their eco-friendly practices. Ask about their sourcing of raw materials, energy use, and waste management strategies. Verify if they use non-toxic, biodegradable ingredients and adhere to environmental certifications.

Establish clear communication channels from the start. Whether it's through email, phone, or video calls, ensure the manufacturer is responsive and open to feedback. Building a good relationship helps address concerns promptly, whether it's about product defects, delays, or adjustments to your order.

More Related...

Confused about tariffs on Chinese toys? This article breaks down current rules, exemptions, and how toy imports are affected.

Learn which toys help children with ADHD stay engaged, manage energy, and develop focus, social skills, and creativity.

Montessori education and sensory play explained, including when and how playdough and other tactile materials support development.

Art and craft in education inspire creativity, fine motor skills, and teamwork, using fun tools like air dry clay, slime, and sensory sand.

Our team will answer your inquiries within 48 hours.

Copyright © 2026 GuangDong AKIA Technology Co,. Ltd. All Rights Reserved